12/01/2026

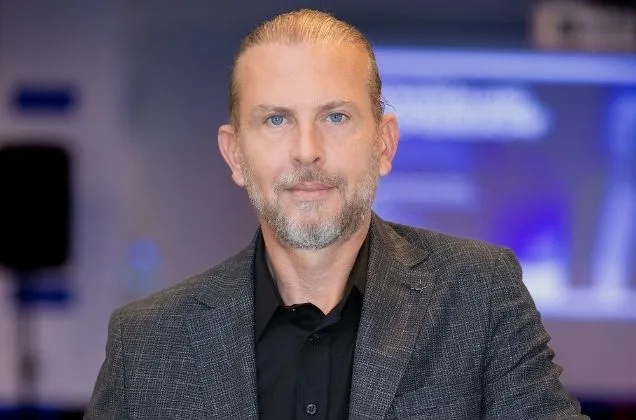

Outstanding Scholar Award: Erhan Budak

"I manufacture, therefore I am

Prof. Dr. Erhan Budak, a faculty member at Sabancı University's Faculty of Engineering and Natural Sciences, is one of the leading scholars in Türkiye and the world in the field of machining and machine tools. The pioneering structures he has brought to our university, especially the Manufacturing Research Laboratory, are a concrete expression of his never-ending curiosity for learning, teaching, and manufacturing.

We met with Professor Budak at the Manufacturing Research Laboratory, which he founded. Before me stood not a "great" professor who had been awarded the Outstanding Scholar Award, but a humble engineer working diligently in his workshop.

A Standard Question

While university graduates in our country have been yearning to go abroad in recent years, I was naturally curious why Professor Budak decided to return to his home country from Canada, especially since he was working under attractive conditions at a reputable company like Pratt & Whitney Canada, which manufactures jet engines in Canada. His answer was as follows: “While working in industry, I always had the desire to return to the academic world. Industrial experience is very important and valuable; it adds a great deal to a person's practical skills. However, I had a desire to develop international research and education programs that would appeal to a wider audience. At that time, I received an invitation from Sabancı. It was a newly established university. It did not have a Mechanical Engineering department, but I thought I could be useful in establishing the Industrial and Mechatronics Engineering programs. Later, we also ensured the establishment of the Manufacturing Engineering program at the master's and doctoral levels. I have tried and continue to try to meet expectations as a faculty member, researcher, and manufacturer.”

Curiosity, a constant drive for studying and learning

I couldn't help but ask him about the secret to his successful career as an academic, researcher, and manufacturer. His answer was a lesson for those dedicated to science: “The strongest driving force is being curious and constantly seeking innovation without being content with what already exists. And hard work is essential for success. Continuous learning is also a crucial component. In the Manufacturing Research Laboratory, while developing innovative, precise, and fast production techniques, we also create simulations using machine learning, a methodology of artificial intelligence. Since these methods are based on mathematical models of manufacturing processes and machines, they provide much faster and more efficient results than trial-and-error approaches and can create solutions to various problems. As you know, artificial intelligence is fed by data. Thanks to models, we have managed to achieve very high accuracy with a smaller amount of experimental data. In this process, we are constantly learning, continuing to learn, and of course, sharing the results.”

Determination and consistency are also keys to success. His determination regarding his desired field of study is clearly evident in this statement: “I had a goal of becoming a mechanical engineer. I got accepted to METU (Middle East Technical University). After receiving my undergraduate degree, I continued at the same university for my master's degree. My master's advisor was Prof. Dr. Nevzat Özgüven, and I completed my thesis on mechanical vibrations with him. The knowledge, and the education at METU in general, were very helpful in my subsequent doctoral and other studies.”

PhD and Industry Experience in Canada

Erhan Budak, who wanted to pursue his PhD abroad, was accepted to the prestigious University of British Columbia. He briefly described his time in Canada as follows: “I completed my PhD at the Manufacturing Automation Laboratory at the University of British Columbia in Canada, focusing on the modeling, analysis, and improvement of the efficiency of machining processes and machine tools. My PhD advisor, Prof. Dr. Yusuf Altıntaş, provided great support, and I learned a great deal from him. My PhD dissertation was sponsored by Pratt & Whitney Canada, so I focused particularly on the production of aircraft engine parts. One of the biggest problems in the production of such parts is vibrations called chatter, which can cause significant damage and losses. An analytical method I developed during my thesis offered a quick way to avoid these vibrations without sacrificing efficiency, and it is now widely used in many places. After my PhD, I started working in the Manufacturing R&D department of the same company. There, we applied the mathematical models, measurement techniques, and simulations I designed to manufacturing. As a result, production costs decreased, manufacturing speed increased, and noticeable improvements in quality occurred. My goal was to return to academia quickly, but since I achieved very good results from my work, I worked there for six years. Aircraft engines don't tolerate mistakes. That's why I gained invaluable experience in flawless manufacturing, in other words, precision."

Establishment of the Laboratory

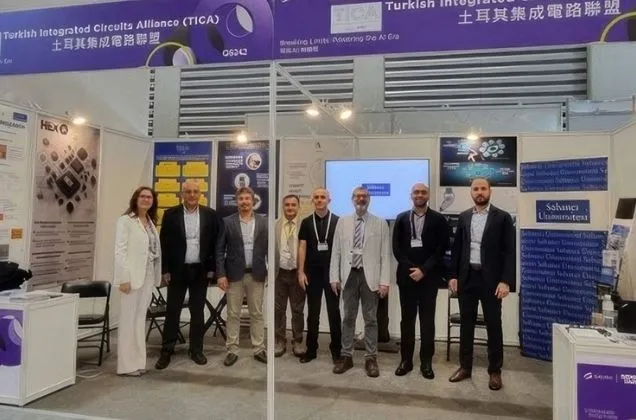

While he was leading the establishment of the Mechatronics and Industrial Engineering programs at Sabancı University, the establishment of the Manufacturing Research Laboratory also began. Dr. Budak states that despite the big investment required for such a lab, they reached an advanced level internationally thanks to various supports, and that they ensured the lab's sustainability through innovative solutions. He explains that the laboratory has reached the current level with various national and international research funding sources and industry support, and that they work closely with sectors such as aviation, machinery, automotive, machine tools, cutting tools, energy, and software. In addition to project support from these companies, they have also acquired donated equipment and tools for the lab. He also emphasizes that Sabancı University has provided very important contributions and support to the laboratory since its establishment. He also highlights the significant contributions of master's and doctoral students and lab personnel to all these developments.

The Laboratory's Main Functions

The Manufacturing Research Laboratory currently provides services through 4 main branches. Professor Budak summarizes the lab's functions as follows:

*Education. Manufacturing techniques are taught in groups. Students machine the parts they create in design applications on industrial-level CNC machines and have the opportunity to observe real manufacturing firsthand. In addition, undergraduate graduation projects are also carried out in the laboratory environment on different processes and machines. In master's and doctoral level courses, experimental studies are conducted using detailed measurement techniques, and the data obtained are used in the study and teaching of metalworking mechanics. In addition to these, industry-oriented training programs such as machining, machine dynamics, process modeling and optimization, etc., are also provided in the lab or in companies.

*Research. Laboratory research focuses particularly on virtual manufacturing and digitalization. Developing models of various machining processes and combining them with machine learning methods allows for testing in a virtual environment before physical production begins, identifying potential problems and opportunities, and selecting the best conditions to increase efficiency. The results of this research have significant impacts on efficiency, cost, and quality, especially in the machining of delicate and complex parts and challenging materials such as titanium and nickel alloys. These studies are conducted through national and international collaborations with master's, doctoral, and postdoctoral researchers, utilizing various funding sources.

*Machine shop. This is the university's only lab that meets the mechanical manufacturing needs. The production of systems, designs, and parts needed in various labs, projects, theses, courses, etc., is carried out by two permanent technicians. These technicians also play a crucial role in meeting the lab's physical requirements, solving infrastructure problems, and supporting research projects and students. Their contribution to the lab's current state is invaluable. The Manufacturing Research Laboratory, which also provides similar services to other centers, also supports student clubs.

*Industrial Support and Interaction: Projects, theses, experimental and theoretical studies conducted in the lab are carried out in interaction with industry as much as possible. In this way, it is ensured that the results are as relevant as possible to the needs of the industry and suitable for application. In this regard, our spin-off company Intemo plays an important role in developing and transferring solutions to the industry, especially in the application of intelligent monitoring systems based on machine learning, towards the long-awaited ultimate goal of unmanned manufacturing (dark factories). In addition, some methods we have developed to solve quality problems and increase efficiency are converted into patents and made available to companies. Similarly, some software developed is also used in industrial applications. The lab makes an important contribution to the preliminary testing of all these.

What does Professor Erhan Budak expect from the future?

In an interview with TTmagazin, our professor summarizes his plans for the future as follows:

Continue producing! A person who produces ideas, models, methods, teams, equipment, etc., is a happy person; a productive society looks to its future with confidence. I believe that by thinking, producing, and creating together, we will see much better days. It is certain that every society, and especially a country like ours with a young population and strategic location, must produce, not just as an option but as a necessity. We need to set this as a goal and stand behind it in every aspect. I think we will be happier by producing more efficiently, more innovatively, and protecting the environment, and by sharing the results fairly. After all, isn't that our purpose in life?

https://www.ttmagazin.com/prof-dr-erhan-budak

Sabancı University and Erhan Budak

Erhan Budak, who joined Sabancı University in 2000 and established the Manufacturing Research Laboratory, was awarded the Taylor Medal by the International Academy for Production Engineering (CIRP) (www.cirp.net) in 2003 for his work in the field of manufacturing complex aircraft engine parts. He was also awarded the medal in 2018 for his contributions to the field of machining.

Erhan Budak has nearly 300 scientific publications and conference papers on machining and machine tools. With over 10,000 citations to these publications, his H-index is close to 65 (Google Scholar). His areas of interest include intelligent manufacturing, machine tools, machining, process modeling and simulation, precision and high-speed manufacturing. Erhan Budak serves as an associate editor or on the editorial board of several leading international journals in the field of manufacturing engineering.

A team of scientists from the United States and the Netherlands identified the world's most influential scientists. The study, which listed the 100,000 most influential scientists in the world across 22 main disciplines and 176 sub-disciplines, was coordinated by Stanford University, and Erhan Budak was included in the list, which features 196 scientists from Türkiye.

He was awarded the Outstanding Scholar Award within the scope of the 2025 Sabancı University Awards in Arts and Sciences.

Sources :

https://www.youtube.com/watch?v=pkifwxrmO2o

http://myweb.sabanciuniv.edu/ebudak/